What is sintered stone? It’s a man-made ultra compact surface engineered for durability. It’s been around for a few years now, so if you haven’t fabricated with it already, you may be soon. Either way, you’re going to want to learn how to cut sintered stone the right way. With your craftsman’s skills and the right tools, you’ll get the most out of this awesome material.

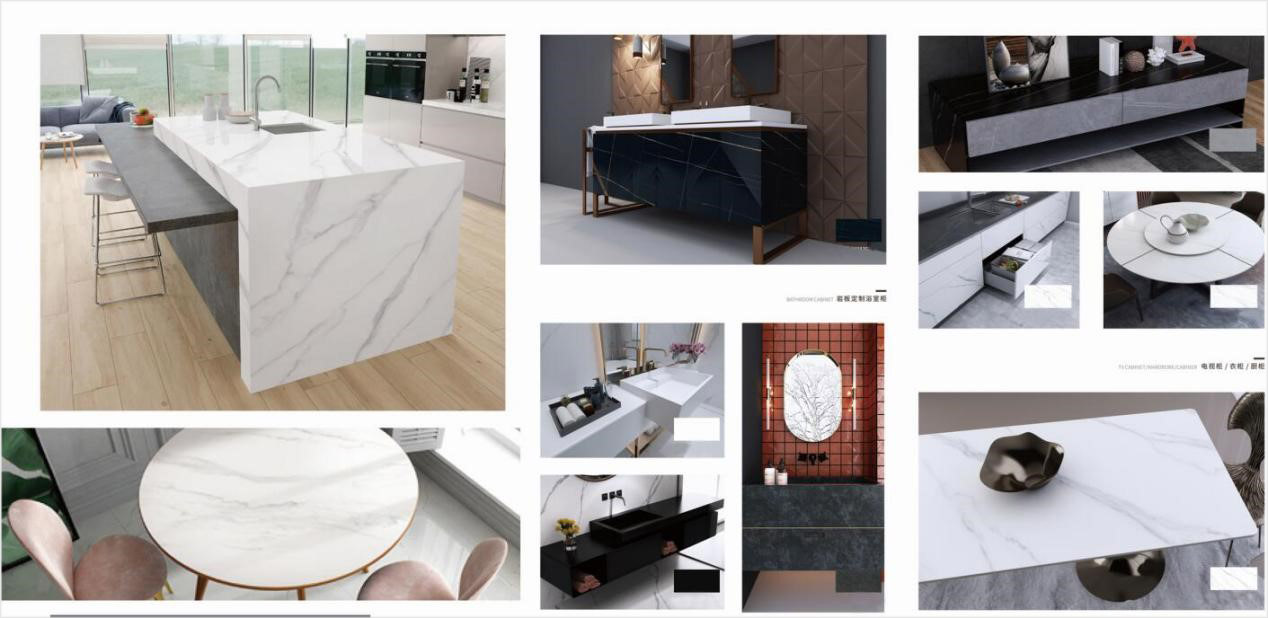

What makes sintered stone such a great material is its durability and versatility. Sintered stone is used for residential and commercial use, indoor and outdoor even the furniture. And it’s been around long enough that the color and texture choices are very well developed. Shops worldwide are selling sintered stone furnature,and installing sintered stone countertops, floors, walls, and exterior architectural cladding.

The Challenges of Sintered Stone

The unique properties of sintered stone can make it one of the most unforgiving slabs to cut.

For example, some slabs have a pattern printed on the surface. Any chips or imperfections on these can ruin the appearance after edge lamination. For other sintered stone materials like Neolith that have designs running through the slab, you’re still going to want perfectly straight cuts to make your finished product look its best.

If you get the cuts right, the quality of your finished work will be top-tier. You’ll have all the work in sintered material you can handle. Get it wrong and you’ll likely do whatever it takes to avoid the material on future jobs.

Even if you have a bridge cutting machine or a water knife machine cutting tool, but the cutting speed is very slow, low efficiency, cutting material consumption, so the processing cost is very high.

How to Cut Sintered Stone more quickly and low cost

Success on this material is simple: straight and shaped cuts.

Super clean straight and shaped cuts are a must for the high-end results that get you referrals. To get those precise cuts you need the right equipment. If you already have an automatic sintered stone cutting machine, you’re set. If you don’t then consider investing in one. The automatic sintered stone cutting machine’s high precision and rigidity are unmatched. The cutting speed is up to 180 meters per minute,We’ve done extensive testing of our machine on sintered stone materials. We’re confident you’ll get the same excellent results our customers are getting across the China.

Architectural glass,car glass,furniture glass,craft glass,decorative glass,cupboard glass, hollow glass,spliced mirror

Post time: Jan-08-2021