Products

-

Model CNC2721 Glass cutting machine for flat glass mirrior

This model is a glass cutting machine. Intelligent optimization of layout and cutting, air floating function, the table is equipped with breaking top rod, convenient for breaking operation after cutting.

This model is a glass cutting machine. Intelligent optimization of layout and cutting, air floating function, the table is equipped with breaking top rod, convenient for breaking operation after cutting.

It is suitable for straight and shaped cutting of glass in construction,decoration, home appliances, mirrors,

and crafts.Our Advantages

Automatic cutting:

Automatic cutting:

The machine can automatically position, scan and cut the glass.Automatic oil filling function and automatic constant pressure adjustment function:

*effectively guarantee cutting stability and cutting effect.Intelligent software:

*Automatic scanning glass shape, all kinds of glass can be cut.

*Automatic typesetting

*Automatic optimization,greatly saving the cost of the use of the original glassIntelligent cutting:*The equipment and computer linkage closed-loop, high-precision andhigh-speed cutting.

*Fool-like operation,straight cutting, profiled cutting.

*With automatic laser positioning, graphics scanning and

other latest features.

Brand electrical pneumatic components:

Brand electrical pneumatic components:*effective protection of cutting accuracy and stability, to meet the various shapes of glass cutting.

- Industrial integrated beam

*Gantry milling processing a molding, no splicing, no welding

*No rust, no deformation

*Ensure cutting speed, cutting stability, cutting accuracy

National carbon steel:

National carbon steel:*Standardized welding

*after annealing treatment

*aging deformation

*stable frame deformation, long service life

Product Parameters

Table height Weight Power Compressed air 880±30mm(Adjustable feet) 900kgs 6kW(Use power4KW) 0.6Mpa Detailed Photos

Flotation device:

*more than 100 stomata evenly arranged in the cutting table to ensure the stability of the air, push and pull the glass is very simple.

*With internal air pump and air intake filter device to ensure stable and effective cutting, reduce the failure rate.

Pneumatic Breaking:

*It greatly improves work efficiencyCertifications

Company Profile

Shandong Huashil Automation Technology Co., LTD., is an excellent domestic comprehensive glass deep processing professional equipment and system solution provider integrating R&D, manufacturing, sales and technical services of glass deep processing equipment. It is the ” National High-tech Enterprise” , ” Province of Specialization, the New Enterprise” . The company always adheres to technological innovation as the core and market demand as the guide, constantly improves the technical content and quality level of products, and promotes the development of high-end and intelligent products and services.

Shandong Huashil Automation Technology Co., LTD., is an excellent domestic comprehensive glass deep processing professional equipment and system solution provider integrating R&D, manufacturing, sales and technical services of glass deep processing equipment. It is the ” National High-tech Enterprise” , ” Province of Specialization, the New Enterprise” . The company always adheres to technological innovation as the core and market demand as the guide, constantly improves the technical content and quality level of products, and promotes the development of high-end and intelligent products and services.The company is located in the Industrial Park of Rizhao High-tech Zone, Shandong Province with convenient transportation . It has modern standard workshops and advanced processing equipment. With an annual output of more than 1,000 units/sets of smart glass equipment, it serves more than 5,000 domestic glass deep processing users, and its products are sold to more than 80 countries and regions around the world.

It mainly develops and produces glass cutting lines, intelligent glass storage, intelligent glass slicing systems, intelligent glass laser marking machines, glass loading and cutting machines, glass bilateral edge grinding line, and large-scale glass deep processing non-standard whole-factory connections,the complete set of glass deep processing equipment and so on.

The company focuses on product quality and brand building, has passed ISO9001 quality management system certification, and has obtained a number of national patents. The company adheres to the business philosophy of “customer first, quality first” and is committed to providing customers with high-quality and efficient glass processing solutions.

In the future development, Huashil Technology will continue to adhere to technological innovation, continuously improve product quality and market competitiveness, and provide better products and services to global customers. At the same time, the company will also actively fulfill its social responsibilities, promote the sustainable development of the industry, and create a better living space for mankind.

- Industrial integrated beam

-

Huashil Model 3826 CNC Glass Automatic Loading and Cutting Machine

This model is a glass cutting machine, which integrates automatic glass loading, automatic labeling, telescopic arm function, and automatic cutting machine.

It is suitable for straight and shaped cutting of glass in construction,decoration, home appliances, mirrors,

and crafts.Automatic load glass , smart suck

glass:*loading:A key to open, the machine automatically raised the arm,automatic walking rotation to find the glass position and angle

*monitor:Equipped with a suction monitoring system. After checking the suction,automatically puting the glass on the cutting table.

Glass sucker use the imported high-strength silica gel:

*the temperature -30 degrees - 200 degrees, it is durable, tear-resistant,not easy to aging.Automatic cutting:

The machine can automatically position, scan and cut the glass.Automatic oil filling function and automatic constant pressure adjustment function:

*effectively guarantee cutting stability and cutting effect.Intelligent software:

*Automatic scanning glass shape, all kinds of glass can be cut.

*Automatic typesetting

*Automatic optimization,greatly saving the cost of the use of the original glassIntelligent cutting:

*The equipment and computer linkage closed-loop, high-precision andhigh-speed cutting.

*Fool-like operation,straight cutting, profiled cutting.

*With automatic laser positioning, graphics scanning and

other latest features.Brand electrical pneumatic components:

*effective protection of cutting accuracy and stability, to meet the various shapes of glass cutting.

Industrial integrated beam

*Gantry milling processing a molding, no splicing, no welding

*No rust, no deformation

*Ensure cutting speed, cutting stability, cutting accuracy

National carbon steel:

*Standardized welding

*after annealing treatment

*aging deformation

*stable frame deformation, long service life

Fault detection system:

*Automatic fault detection

*real-time display of machine status

*easy to use and after-sales maintenance

Intelligent remote control:

*The use of hand-held wireless remote control device, it can move around 360 degrees, start the machine and realize automatic intelligent load and break the glass

Free walking:

*Four groups of drive wheels, 360 degrees around the rotation, can walk freely in the workshopTable height Weight Power Compressed air 880±30mm(Adjustable feet) 2500kgs 15kW(Use power3KW) 0.6Mpa Flotation device:

*more than 100 stomata evenly arranged in the cutting table to ensure the stability of the air, push and pull the glass is very simple.

*With internal air pump and air intake filter device to ensure stable and effective cutting, reduce the failure rate.

Pneumatic Breaking:

*It greatly improves work efficiencyShandong Huashil Automation Technology Co., LTD., is a set of mechanical equipment automation research and development, manufacturing, sales in one of the high-tech manufacturing enterprises,mainly research and development production of a full set of glass deep processing intelligent equipment,such as the glass loading and cutting machine,glass cutting line,glass shuttle warehouse intelligent chip trimming system,glass edging machine,glass double-sided edging machine and so on.We have a wealth of mechanical automation equipment production experience, production capacity, technological level and comprehensive economic strength in the same industry in the forefront of the domestic industry, intelligent automation equipment research and development, material control, equipment performance and modeling has been in the domestic leading level, a number of techniques. have filled the domestic blank. The good after – sales service and reasonable price, for a long time to win the customer’s praise. In line with the principle of “good faith first, customer satisfaction”, our company has established long-term cooperative relations with many enterprises.

-

HSL LSX-2621 Tempered glass cutting line

Automatic loading:The telescopic arm and the big arm extend out at the same time, and automatically find the glass. After the system detects the suction cup firmly, put the glass back to the table automatically, and the upper plate is finished

Intelligent control: one button control can finish the loading, cutting and labeling at one time

Automatic cutting:Intelligent optimization cutting software, optimization rate up to 99%, automatic cutting, high precision, fast speed

Automatic labeling:Intelligent automatic labeling,labeling follows the head of the cutting machine,which has the advantages of fast speed and high stability.

Fault detection: automatic fault detection and alarm system, real-time uploading of fault causes can quickly solve the fault

Technical specification

Machine parameter

Size 13675mm*3483mm*870mm

Max cutting size 4200*2800mm

Min cutting size 1200*1000mm

Table Heigh 900±50mm(Can be adjusted)

Power 380V,50Hz

Installed Power 10kW

Air compression 0.6Mpa

Processing parameters

Cutting size MAX.4220*2800mm

Cutting thickness 2~19mm

X axis speed X轴0~200m/min

Y axis speed Y轴0~200m/min

Cutting acceleration ≥6m/s²

Conveying speed 5-25m/min(Can be adjusted)

Cutting knife holder 360°

Cutting accuracy ≤±0.3mm/m

-

CNC Model 2621 glass cutting machine

This model is a glass cutting machine, which integrates automatic glass automatic labeling and automatic cutting machine. It is suitable for straight and shaped cutting of glass in construction, decoration, home appliances, mirrors, and crafts.

-

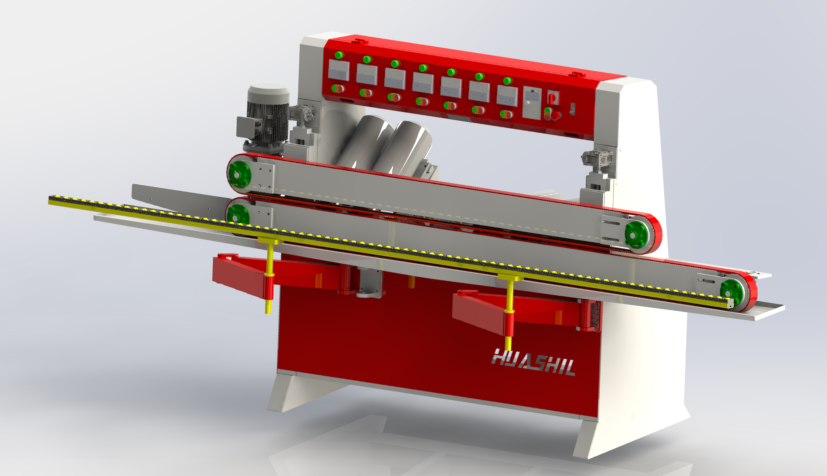

High precision glass double edger machine

High precision glass double edger machine

Safety, durability, high efficiency, professional design, small size and large energy

Application:

The High precision glass double edger machine can be applied to the following areas:

Craft glass

Small pieces of glass crafts edge grinding

Home decorated glass

Home decorated glass , home glass edging

Architectural decoration

Building decoration, mirror、 Ceramic tile、 composite ceramic tile、 artificial stone、 microcrystalline stone edge grinding

Deep processing of glass and other industries

Description:

The High precision glass double edger machine is suitable for grinding flat glass with double straight sides.

Rough grinding, fine grinding, polishing safety angle (installed safety chamfering wheel) once completed.

Grinding head sliding with double straight rolling guide, double ball screw drive to reach a stable moving speed, eliminate mobile clearance, reduce resistance and friction, to ensure repeat positioning.

PLC control system set the processing parameters by the interface to complete the processing.

The use of automatic compensation polishing brake mechanism to ensure the surface finish after grinding. Width opening and closing and crawler drive using high-power inverter motor. Speed control, constant power, constant twist rejection output, stable and reliable.

Features:

- a stable and solid structure

- accurate and smooth rotation system,

- high configuration of the control system

- large size of the processing capacity

-

Double head glass film removing and glass cutting machine

HSL-YTJ2621 Automatic Glass Cutting Machine

- This model is a glass cutting machine, which integrates automatic glass loading, automatic labeling, telescopic arm function, and automatic cutting machine. It is suitable for straight and shaped cutting of glass in construction, decoration, home appliances, mirrors, and crafts.

Equipment Introduction Equipment footprint: 17 square meters Note Operator: Glass breaking:2 people(People with glass breaking experience can make better use of cutting efficiency) Features 1、The absolute value motors and imported high-precision racks and other top-level components effectively guarantee the accuracy and stability of glass cutting, have a longer service life and can meet the cutting of various shapes of glass;2、Integrated rail, exclusive patent, cut glass has higher precision; 3、The machine table is made of waterproof, fireproof, high and low temperature resistant, and anticorrosive materials, which will never deform;

4、Infrared scanning point function and infrared scanning special-shaped template function;

5、Highly intelligent cutting machine optimization software, which greatly improves glass utilization and reduces production costs;

6、Air-floating function, improve work efficiency, comes with automatic loading machine and separation machine;

7、Automatic oil injection and automatic pressure adjustment function of cutting machine, effectively guarantee cutting stability and cutting effect;

8、There are no special requirements for operators, simple operation and easy management.

Category Project Project Instruction Functions

Standard functions

Cutting optimization software 1.Professional glass cutting and optimized typesetting function: greatly improve glass cutting rate and production efficiency.2.Compatible with Italian OPTIMA optimized software and domestic GUIYOU software’s standard G code: Realize the universality of different format files. 3.Fault diagnosis and alarm function: It can automatically record the running status of the machine in the production process, fault alarm and display problems.

Fiber laser positioning - Automatic edge-finding and positioning of glass: Precise measurement of the actual position and deflection angle of the glass, realizing automatic adjustment of the cutting path of the blade, and improving efficiency

2. Intelligent shaped scanning: The detector can intelligently scan the shaped objects and automatically generate graphics to realize contour cutting.

Cut technology The cutting blade pressure is controlled by an electromechanical precision pressure regulating valve, and the cylinder pushes the pressure uniformly to make the blade perfectly fit the surface of the glass to cut, avoiding skipping due to glass quality problems. Optional function

Telescopic arm function High precision pinion and rack drive is adopted to replace the original screw drive, each time the loading is completed by the telescopic arm movement, the machine does not need to move. It can be controlled by computer autonomously, and automatic loading and cutting can be completed without manual intervention, which greatly improves efficiency; Due to the reduction of the number of walks, the mechanical wear is greatly reduced and the life and stability of the machine are improved. Automatic labeling Replace manual labeling. According to customer requirements, the printer prints labels that record glass information.The label is applied to the corresponding glass surface by the labeling cylinder.(We recommend customers to configure the labeling function) Glass breaking function Install the ejector rod on the cutting platform. The cylinder pushes the ejector rod to disconnect the glass. TransportFeatures The cutting beam is equipped with the conveyor sucker. There is no need to manually move the glass. The cutted glass can be transferred to the air floating glass breaking table through the conveyor sucker, and the breaking operation is performed on the glass breaking table. Category Project Project Instruction

Note Product configuration

Mechanical part

Machineframe Aging treatment after welding of thicker sections. The side beam fixing plate is processed by gantry milling to ensure accuracy and stability. Flat beam X-axis and Y-axis running flat beams adopt unique patented aluminum alloy profiles, which have high strength and high precision, and are durable and stable. Rack Adopting helical rack and pinion structure to improve tooth surface strength and effectively reduce noise Oil supply The oil supply of the cutting blade adopts the pneumatic automatic oil filling method, without manual intervention. Fan Customized high-power fan, high wind pressure and large flow, ensure smooth glass floatation. Cutting drive motor 2 set high performance industrial control dedicated servo motor for precise control and smooth operation. Mesa The high-density waterproof board is a substrate, and the surface is covered with an anti-static industrial felt. Ensure stable use in humid environments. Electrical parts

Host computer High-performance computer host for industrial control; brand high-resolution display. Controller - Huashil special control board card, perfect match Toshiba PLC control system.

Optical fiber Uses Panasonic laser detectors imported from Japan. Element Imported international first-line brand control components such as OMRON, Panasonic. Technical Parameters

Machine parameters

Dimensions Length * width * height:3000mm*4700mm*1420mm Table height 880±30mm(Adjustable feet) Power requirements 3P,380V,50Hz Installed power 13kW(Use power3KW) Compressed air 0.6Mpa Processing parameters

Cut glass size MAX.2440*2000mm Cut glass thickness 2~12mm Head beam speed X axis 0 ~ 200m / min (can be set) Head speed Y axis 0 ~ 200m / min (can be set) Cutting acceleration ≥6m/s² Cutting knife seat Cutting head can rotate 360 degrees (precise cutting of straight lines and special shapes) Cutting accuracy ≤±0.25mm/m(Based on the size of the cutting line before the glass breaking) -

-

Double side loading four stations Glass cutting line glass cutting machine

Automatic loading:The telescopic arm and the big arm extend out at the same time, and automatically find the glass. After the system detects the suction cup firmly, put the glass back to the table automatically, and the upper plate is finished

Intelligent control: one button control can finish the loading, cutting and labeling at one time

Automatic cutting:Intelligent optimization cutting software, optimization rate up to 99%, automatic cutting, high precision, fast speed

Automatic labeling:Intelligent automatic labeling,labeling follows the head of the cutting machine,which has the advantages of fast speed and high stability.

Fault detection: automatic fault detection and alarm system, real-time uploading of fault causes can quickly solve the fault

Technical specification

Machine parameter

Size 13675mm*3483mm*870mm

Max cutting size 4200*2800mm

Min cutting size 1200*1000mm

Table Heigh 900±50mm(Can be adjusted)

Power 380V,50Hz

Installed Power 10kW

Air compression 0.6Mpa

Processing parameters

Cutting size MAX.4220*2800mm

Cutting thickness 2~19mm

X axis speed X轴0~200m/min

Y axis speed Y轴0~200m/min

Cutting acceleration ≥6m/s²

Conveying speed 5-25m/min(Can be adjusted)

Cutting knife holder 360°

Cutting accuracy ≤±0.3mm/m

-

CNC Automatic Loading and Cutting Glass cutting machine

Automatic loading:The telescopic arm and the big arm extend out at the same time, and automatically find the glass. After the system detects the suction cup firmly, put the glass back to the table automatically, and the upper plate is finished

Intelligent control: one button control can finish the loading, cutting and labeling at one time

Automatic cutting:Intelligent optimization cutting software, optimization rate up to 99%, automatic cutting, high precision, fast speed

Automatic labeling:Intelligent automatic labeling,labeling follows the head of the cutting machine,which has the advantages of fast speed and high stability.

Fault detection: automatic fault detection and alarm system, real-time uploading of fault causes can quickly solve the fault

Automatic walking:The walking wheel is driven by two sets of high-horsepower motors, which can rotate and walk 360 degrees

Automatic Glass Cutting Machine

High efficiency, high quality and high precision.

Fully independent research and development, design, production, can be customized according to the special needs of users.

Specially developed 6mm thick 6061 high strength industrial aluminum beam to remove internal stress, to ensure the service life and load-bearing capacity of aluminum beam, large milling machine processing installation surface, to ensure the perpendicularity and straightness of the installation surface, improve the accuracy

Adopt high strength national standard carbon steel, robot full welding process, the whole body heat treatment, stress removal aging treatment, to ensure the body stability and flatness

The core parts of the printer are perfectly combined with the machine head,labeling follows the head of the cutting machine,which has the advantages of fast speed and high stability.

Adopt dual-screen control system. The security alarm system and fault detection system are equipped with network central controller and connected with big data of the company, which can monitor and deal with the production fault of the equipment remotely. Professional glass optimization software system, optimization rate up to 99%.

Adopt HD industrial display screen, aluminum alloy profile shell, explosion-proof, dustproof, super long service life. Ultra wide viewing Angle and ultra high display brightness.

Intelligent glass cutting machine

Automatic glass cutting machine

Our company with Shanghai Weihong, Shenzhen Gugao joint research and development of cutting system, with small floor space, long service life, stable performance and other advantages, optimization rate up to 99%.

Brand electrical components: adopt first-line brand electrical components, electrical lines quick plug design, convenient to replace the aging circuit quickly

Super silent drag chain

Waterproof table

Optimization arrangement-cost savingLibrary with various of common shaped outlines-convenient and fast

Collection and processing of special shaped outlines-concise and effective

Laser-positioning cutting without any restraint

Intelligent printing and labeling saving and environmental protection

Intelligent loading-accurate and correct

Automatic walking-fast and efficientApply to industry

Architectural glass,car glass,furniture glass,craft glass,decorative glass,cupboard glass, hollow glass,spliced mirror -

Tempered glass insulating glass Automatic labeling glass cutting line glass cutting machine

Automatic loading:The telescopic arm and the big arm extend out at the same time, and automatically find the glass. After the system detects the suction cup firmly, put the glass back to the table automatically, and the upper plate is finished

Intelligent control: one button control can finish the loading, cutting and labeling at one time

Automatic cutting:Intelligent optimization cutting software, optimization rate up to 99%, automatic cutting, high precision, fast speed

Automatic labeling:Intelligent automatic labeling,labeling follows the head of the cutting machine,which has the advantages of fast speed and high stability.

Fault detection: automatic fault detection and alarm system, real-time uploading of fault causes can quickly solve the fault

Technical specification

Machine parameter

Size 13675mm*3483mm*870mm

Max cutting size 4200*2800mm

Min cutting size 1200*1000mm

Table Heigh 900±50mm(Can be adjusted)

Power 380V,50Hz

Installed Power 10kW

Air compression 0.6Mpa

Processing parameters

Cutting size MAX.4220*2800mm

Cutting thickness 2~19mm

X axis speed X轴0~200m/min

Y axis speed Y轴0~200m/min

Cutting acceleration ≥6m/s²

Conveying speed 5-25m/min(Can be adjusted)

Cutting knife holder 360°

Cutting accuracy ≤±0.3mm/m

-

Mirror cutting machine Automatic Glass Cutting Machine

Automatic loading:The telescopic arm and the big arm extend out at the same time, and automatically find the glass. After the system detects the suction cup firmly, put the glass back to the table automatically, and the upper plate is finished

Intelligent control: one button control can finish the loading, cutting and labeling at one time

Automatic cutting:Intelligent optimization cutting software, optimization rate up to 99%, automatic cutting, high precision, fast speed

Automatic labeling:Intelligent automatic labeling,labeling follows the head of the cutting machine,which has the advantages of fast speed and high stability.

Automatic walking:The walking wheel is driven by two sets of high-horsepower motors, which can rotate and walk 360 degrees

Fault detection: automatic fault detection and alarm system, real-time uploading of fault causes can quickly solve the fault

Automatic Glass Cutting Machine

High efficiency, high quality and high precision.

Fully independent research and development, design, production, can be customized according to the special needs of users.

Specially developed 6mm thick 6061 high strength industrial aluminum beam to remove internal stress, to ensure the service life and load-bearing capacity of aluminum beam, large milling machine processing installation surface, to ensure the perpendicularity and straightness of the installation surface, improve the accuracy

Adopt high strength national standard carbon steel, robot full welding process, the whole body heat treatment, stress removal aging treatment, to ensure the body stability and flatness

The core parts of the printer are perfectly combined with the machine head,labeling follows the head of the cutting machine,which has the advantages of fast speed and high stability.

Adopt dual-screen control system. The security alarm system and fault detection system are equipped with network central controller and connected with big data of the company, which can monitor and deal with the production fault of the equipment remotely. Professional glass optimization software system, optimization rate up to 99%.

Adopt HD industrial display screen, aluminum alloy profile shell, explosion-proof, dustproof, super long service life. Ultra wide viewing Angle and ultra high display brightness.

Intelligent glass cutting machine

Automatic glass cutting machine

Our company with Shanghai Weihong, Shenzhen Gugao joint research and development of cutting system, with small floor space, long service life, stable performance and other advantages, optimization rate up to 99%.

Brand electrical components: adopt first-line brand electrical components, electrical lines quick plug design, convenient to replace the aging circuit quickly

Super silent drag chain

Waterproof table

Optimization arrangement-cost saving

·Library with various of common shaped outlines-convenient and fast

·Collection and processing of special shaped outlines-concise and effective

·Laser-positioning cutting without any restraint

·Intelligent printing and labeling saving and environmental protection

·Intelligent loading-accurate and correct

·Automatic walking-fast and efficientApply to industry

Architectural glass,car glass,furniture glass,craft glass,decorative glass,cupboard glass, hollow glass,spliced mirror -

HSL-CNC3826 Automatic Glass Cutting Machine

This model is a glass cutting machine, which integrates automatic glass automatic labeling and automatic cutting machine. It is suitable for straight and shaped cutting of glass in construction, decoration, home appliances, mirrors, and crafts.