With the popularity of the sintered stone, sintered stone processing splicing process equipment also gradually entered the market, to recommend to you a very practical sintered stone edge grinding equipment, 45 degrees compared to with the saw blade cutting edge grinding, replace the saw blade more than high cost, and edge grinding effect is not ideal, mainly because the machine cutting and edge grinding wheel is hang on the machine, the machine running for a long time after the machine will get bending beam and straightness.

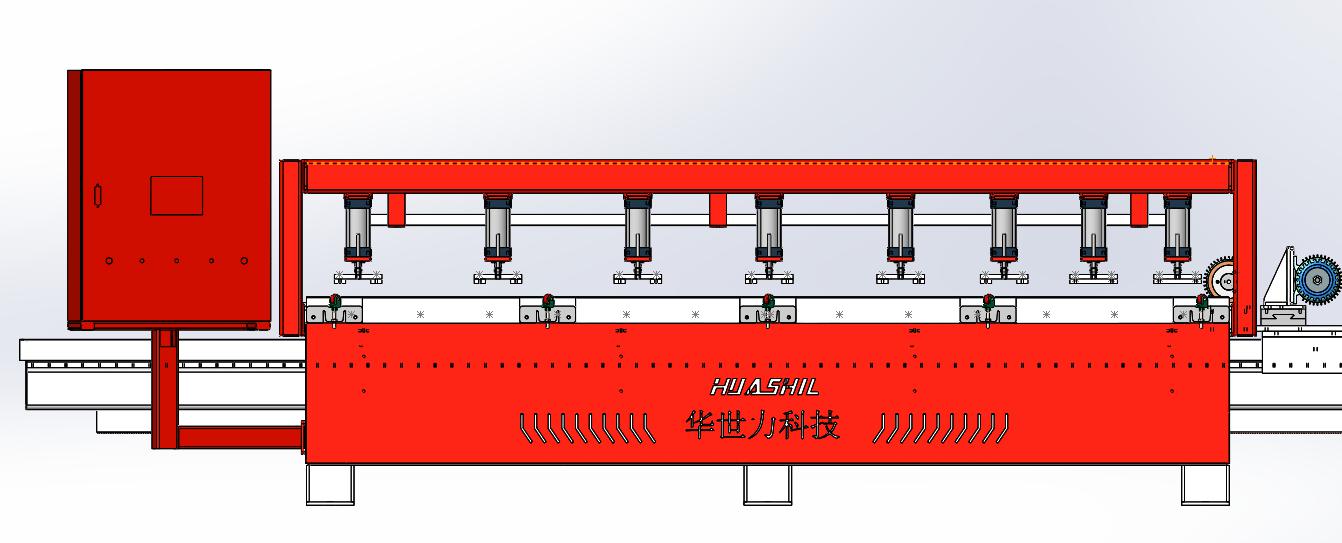

Huashil sintered stone 45 degree edging machine,This edge grinding machine I recommend to you,fool-style operation, cylinder + gear positioning, various shapes, plate thickness directly grinding, no need to adjust.

The internal oblique angle of 45°is formed once, and it is directly grinding to the surface of the sintered stone without edge breaking.

Super strong frame, the whole machine frame is made of super large steel welding,

After heating and aging treatment, through the gantry finished, and the frame weight nearly 3 tons.

Adopt Taiwan Hiwin guide rail rack, adopt oil bubble + waterproof cover design, not afraid of dirty water corrosion

Ultra-low consumable cost, patent customized special grinding wheel, low practical cost.

Let's have a look at the edge grinding effect of the sintered stone 45 degree edging machine

If coupled with automatic sintered stone cutting machine, the perfect combination of low cost sintered stone processing.

Post time: Mar-17-2021