HSL-CNC3826 Automatic Glass Cutting Machine

Accessories

|

No. |

Name |

Qty |

Model |

|

1 |

Cut dongle |

1 |

|

|

Optimize the dongle (according to the system) |

1 |

|

|

|

2 |

Cutting Knife |

2 |

|

|

3 |

Cutting Wheel |

2 |

Yellow wheels (with screws) |

|

4 |

Internal hexagonal wrench |

1 |

|

|

5 |

AC contactor LCIROM5N |

1 |

|

|

6 |

magnetic valve 4V21008B(24V) |

1 |

|

|

7 |

Servo driver specification |

1 |

V6.1 |

|

8 |

Mouse pad, keyboard |

1 |

|

|

10 |

Approach switch |

1 |

|

|

11 |

Cable Ties |

50 |

|

|

12 |

Manual oil can |

1 |

|

|

13 |

Air pipe tee connection quick plug |

1 |

|

|

14 |

Label paper |

5 |

|

Equipment Introduction

This model is a glass cutting machine, which integrates automatic glass automatic labeling and automatic cutting machine. It is suitable for straight and shaped cutting of glass in construction, decoration, home appliances, mirrors, and crafts.

| Equipment footprint: | 7 square meters | ||

| Operator: | Glass breaking:2 people(People with glass breaking experience can make better use of cutting efficiency) | ||

| Features | 1.The absolute value motors and imported high-precision racks and other top-level components effectively guarantee the accuracy and stability of glass cutting, have a longer service life and can meet the cutting of various shapes of glass;2.Integrated rail, exclusive patent, cut glass has higher precision;3.The machine table is made of waterproof, fireproof, high and low temperature resistant, and anticorrosive materials, which will never deform;

4.Infrared scanning point function and infrared scanning special-shaped template function; 5.Highly intelligent cutting machine optimization software, which greatly improves glass utilization and reduces production costs; 6.Air-floating function, improve work efficiency, comes with automatic loading machine and separation machine; 7.Automatic oil injection and automatic pressure adjustment function of cutting machine, effectively guarantee cutting stability and cutting effect; 8.There are no special requirements for operators, simple operation and easy management. |

||

| Category | Project | Project Instruction | |

| Functions | Standard functions | Cutting optimization software | 1.Professional glass cutting and optimized typesetting function: greatly improve glass cutting rate and production efficiency.2.Compatible with Italian OPTIMA optimized software and domestic GUIYOU software's standard G code: Realize the universality of different format files.3.Fault diagnosis and alarm function: It can automatically record the running status of the machine in the production process, fault alarm and display problems. |

| Fiber laser positioning | 1. Automatic edge-finding and positioning of glass: Precise measurement of the actual position and deflection angle of the glass, realizing automatic adjustment of the cutting path of the blade, and improving efficiency2. Intelligent shaped scanning: The detector can intelligently scan the shaped objects and automatically generate graphics to realize contour cutting. | ||

| Cut technology | The cutting blade pressure is controlled by an electromechanical precision pressure regulating valve, and the cylinder pushes the pressure uniformly to make the blade perfectly fit the surface of the glass to cut, avoiding skipping due to glass quality problems. | ||

| Glass breaking function | Install the ejector rod on the cutting platform. The cylinder pushes the ejector rod to disconnect the glass. | ||

| Machine Walking | The bottom frame of the machine is equipped with 4 universal load-bearing nylon wheels to facilitate the customer to push the movement. After positioning, the 4 feet are adjusted to support the stable grip of the machine | ||

| Optional function | Automatic labeling | Replace manual labeling. According to customer requirements, the printer prints labels that record glass information.The label is applied to the corresponding glass surface by the labeling cylinder.(We recommend customers to configure the labeling function) | |

| TransportFeatures | The cutting platform is equipped with the conveyor belt. There is no need to manually move the glass. The cut glass can be transferred to the air floating glass breaking table through the conveyor belt, and the breaking operation is performed on the glass breaking table.(Need to buy air floating glass breaking table) | ||

| Category |

Project |

Project Instruction |

Note |

|

|

Product configuration |

Mechanical part |

Machine frame |

Aging treatment after welding of thicker sections. The side beam fixing plate is processed by gantry milling to ensure accuracy and stability. |

|

|

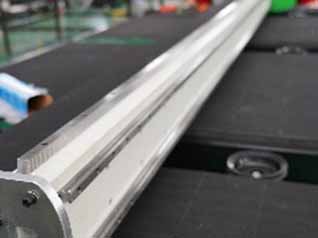

The cutting beam |

Patented industrial aluminum composite T-WIN linear rail, high precision, low noise, the preferred structure of high-end equipment |

|||

|

Side beam |

Patented industrial aluminum composite straight circular rail, rail wheel bearing capacity, rolling along the track, low friction can ensure the stable operation of the cutting bridge |

|||

|

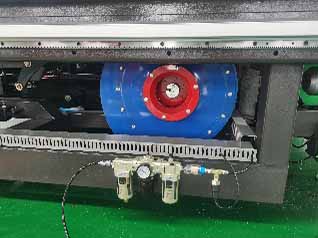

Fan |

Customized high-power fan, high wind pressure and large flow, ensure smooth glass floatation. |

|||

|

Table facet |

The high-density waterproof board is a substrate, and the surface is covered with an anti-static industrial felt. Ensure stable use in humid environments. |

|||

|

Cutting head |

Germany Bohle |

|||

|

Gear Rack |

Adopting helical rack and pinion structure to improve tooth surface strength and effectively reduce noise |

|||

|

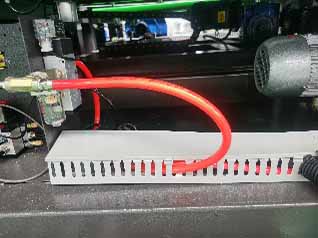

Drag chain |

High strength 7525 silent drag chain |

|||

|

Oil supply |

The oil supply of the cutting blade adopts the pneumatic automatic oil filling method, without manual intervention. |

|||

|

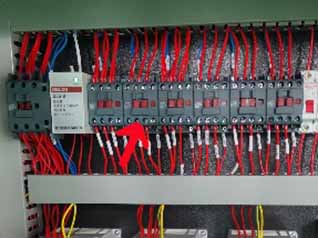

Electrical parts |

Cutting drive motor |

2 set high performance industrial control dedicated servo motor for precise control and smooth operation. |

|

|

|

Controller |

Huashil special control board card, Gugao PLC control system. |

|||

|

Optical fiber |

Uses Panasonic laser detectors imported from Japan. |

|||

|

Display |

Dell display, High definition and stable performance |

|||

|

Host computer |

High-performance computer host for industrial control; brand high-resolution display. |

|||

|

Element |

Imported international first-line brand control components such as OMRON, AirTAC. |

|||

|

Technical Parameters

|

Machine parameters |

Dimensions |

Length * width * height:3350mm*3000mm*1400mm |

|

|

Weight |

1200kg |

|

||

|

Table height |

880±30mm(Adjustable feet) |

|||

|

Power requirements |

380V,50Hz |

|||

|

Installed power |

7.5kW(Use power3KW) |

|||

|

Compressed air |

0.6Mpa |

|||

|

Processing parameters |

Cut glass size |

MAX. 2440*2000mm |

|

|

|

Cut glass thickness |

3~19mm |

|||

|

Head beam speed |

X axis 0 ~ 200m / min (can be set) |

|||

|

Head speed |

Y axis 0 ~ 200m / min (can be set) |

|||

|

Cutting acceleration |

≥8m/s² |

|||

|

Cutting knife seat |

Cutting head can rotate 360 degrees (precise cutting of straight lines and special shapes) |

|||

|

Cutting accuracy |

≤±0.2mm/m(Based on the size of the cutting line before the glass breaking) |

|||

Configuration List