Top Quality Cnc Glass Cutting Table - 3826 Automatic glass cutting line – Huashili

Top Quality Cnc Glass Cutting Table - 3826 Automatic glass cutting line – Huashili Detail:

Intelligent ,high-speed ,good stability, safety and convenience, saving manpower and higher efficiency

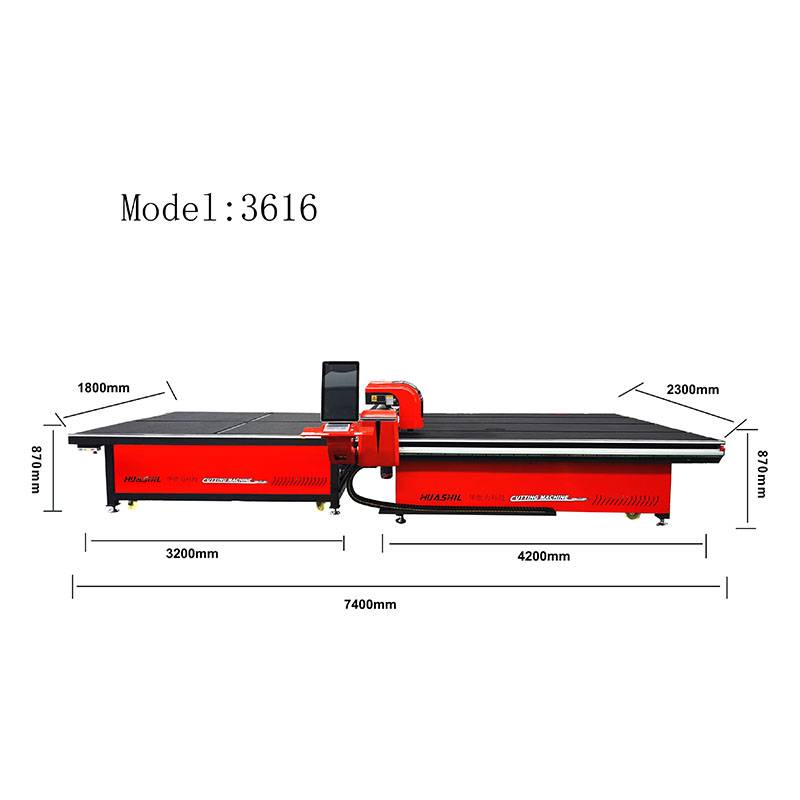

Models can be customized:

Intelligent high-speed glass cutting line consists of automatic glass loading table, automatic glass cutting machine and automatic air breaking table. It is a kind of automatic glass cutting system with automatic loading, automatic typesetting and cutting functions in one.The intelligent cutting line has the advantages of good stability, safety and convenience, saving manpower and higher efficiency, and is the preferred equipment for glass deep processing enterprises.

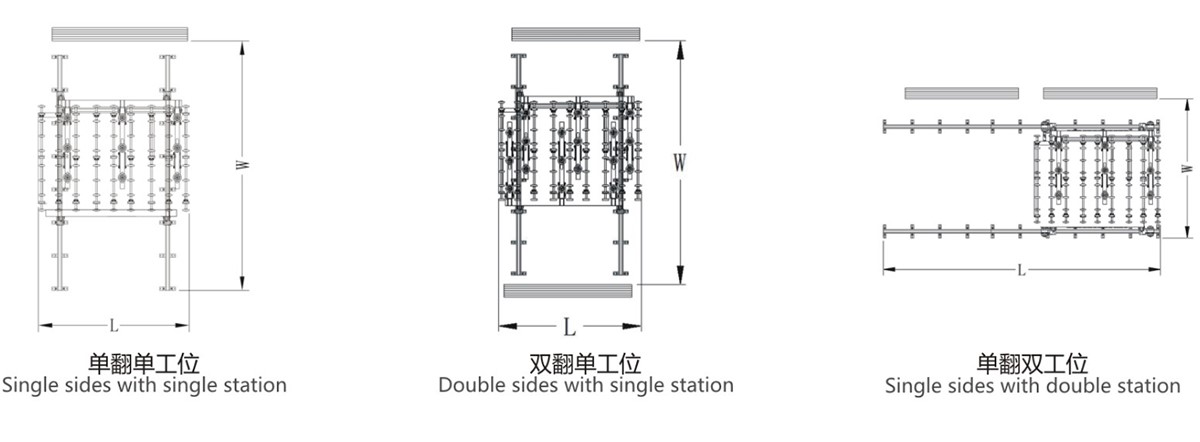

Automatic glass loading platform is a safe, efficient and fast replacement of manual glass cutting equipment, according to the different loading station is often divided into: single turn single station, single turn double station, double turn single-station, double turn double-station.No matter which way the working principle is the same, the customer can make a suitable choice according to the production and site of the processing plant and other factors

Basic working principle:

It is mainly used for automatic glass loading.Put glass in the specified location, after the loading signal is given, The big arm is flipped up by 95°-100° through the overturning mechanism, the machine began to walk forward, while the sensors on the forearm when in contact with the glass, the machine stop walking,the sucker absorbs the glass through the vacuum system,The forearm lifts the glass back and up by about 20mm for separating the glass, delay separating, again on the back rise above 80 mm, after walking motor back arm fall at the same time, after the big arm in place, under the glass sucker began to blow, forearm falling glass land on conveying wheel at this moment, the last, through the delivery send glass to cut on the stage.

Product detail pictures:

Related Product Guide:

Fast and good quotations, informed advisers to help you choose the correct product that suits all your needs, a short production time, responsible quality control and different services for paying and shipping affairs for Top Quality Cnc Glass Cutting Table - 3826 Automatic glass cutting line – Huashili , The product will supply to all over the world, such as: Morocco, Finland, Azerbaijan, Welcome any of your inquiries and concerns for our products. We look forward to establishing a long-term business relationship with you in the near future. Contact us today. We are the first business partner for you!

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.